Carter Band Saw Guides: A Comprehensive Overview

Carter Band Saw Guides represent a significant upgrade for woodworking enthusiasts, offering precision and stability. These guides, stemming from a legacy of quality, enhance cutting accuracy and blade life.

Carter Band Saw Guides have become synonymous with precision and reliability within the woodworking community. These aren’t merely accessories; they are essential components for maximizing the performance and longevity of your band saw. Originally born from a need for improved cutting accuracy, Carter guides address inherent limitations found in standard band saw setups.

The brand’s foundation is deeply rooted in a commitment to quality, a principle instilled by its namesake, Jimmy Carter. These guides offer a substantial improvement over factory-installed options, reducing blade drift and enhancing overall cut quality. Whether you’re a seasoned professional or a hobbyist woodworker, upgrading to Carter guides unlocks a new level of control and precision in your projects. They are available in various series to suit different band saw models and cutting needs.

Historical Context: Jimmy Carter and the Brand

Jimmy Carter, the 39th President of the United States, was a peanut farmer and former Navy officer with a strong work ethic and dedication to practical solutions. While not directly involved in the day-to-day operations, the brand “Carter” embodies these qualities. The company’s origins trace back to a desire for improved woodworking tools, reflecting Carter’s own hands-on approach to life.

Though his presidency focused on human rights and peace, Carter’s legacy extends to a commitment to quality and innovation. The band saw guide company adopted his name, aiming to represent those same values in the manufacturing of precision tools. His long life, reaching 100 years, symbolizes durability – a characteristic mirrored in the robust construction of Carter Band Saw Guides. The brand stands as a testament to a life dedicated to service and practical achievement.

Carter Band Saw Guide Product Lines

Carter Band Saw Guides offers several product lines designed to cater to diverse band saw models and user needs. The Micro Precision Series focuses on exceptional accuracy for intricate cuts, ideal for hobbyists and detailed work. The robust Guidall Series provides reliable performance for general-purpose cutting tasks, offering a balance of precision and durability.

For broader compatibility, the 2000 Series Guides are a popular choice, while specialized 2300 and 2400 Band Saw Guide Parts allow for customized repairs and upgrades. Each line includes essential components like upper and lower guides, and guard attachments. These kits aim to eliminate guesswork and stress when upgrading, providing a seamless experience for improved band saw functionality and cutting performance.

Micro Precision Series Guides

Carter’s Micro Precision Series Guides are engineered for woodworkers demanding the highest level of accuracy. These guides excel in intricate cuts, resawing, and delicate operations where minimizing blade drift is crucial. They feature precision-ground components and tight tolerances, ensuring consistent and clean results.

Designed for optimal blade support, the Micro Precision Series minimizes flex and vibration, extending blade life and improving cut quality. This series is a favorite among those working with valuable hardwoods or requiring tight-fitting joints. The kit typically includes a lower and upper guide, alongside a new guard attachment, providing a complete upgrade solution for enhanced band saw performance and precision.

Guidall Series Guides

Carter’s Guidall Series Guides represent a robust and reliable upgrade for a wide range of band saw applications. These guides strike a balance between precision and durability, making them suitable for both hobbyist and professional woodworkers. They are designed to improve cutting accuracy and reduce blade wander, resulting in cleaner, straighter cuts.

The Guidall series offers enhanced blade support, minimizing flex and vibration during operation. This translates to increased blade life and a smoother cutting experience. Like other Carter kits, the Guidall Series typically includes both lower and upper guides, along with a guard attachment, providing a comprehensive solution for improving band saw performance and achieving professional-quality results consistently.

2000 Series Band Saw Guides

Carter’s 2000 Series Band Saw Guides are a popular choice for woodworkers seeking a significant performance boost for their band saws. These guides are known for their precision engineering and ability to deliver exceptionally straight cuts. They represent a step up in quality and functionality compared to standard band saw guides, offering improved blade control and reduced vibration.

The 2000 Series typically includes a complete kit with both upper and lower guides, along with the necessary hardware for installation. This comprehensive approach ensures compatibility and ease of upgrade. By minimizing blade deflection, these guides contribute to longer blade life and a more efficient cutting process, making them a valuable investment for serious woodworkers.

2300 Band Saw Guide Parts

Carter’s 2300 Band Saw Guide Parts cater to users needing replacements or specific components for their existing 2300 Series guides. These parts are designed to maintain the high precision and performance standards associated with the Carter brand. Offering individual components allows woodworkers to address wear and tear without replacing the entire guide system, providing a cost-effective solution.

Commonly available parts include thrust bearings, guide blocks, and mounting hardware. Utilizing genuine Carter replacement parts ensures compatibility and optimal functionality. Maintaining the integrity of the guide system is crucial for achieving accurate cuts and maximizing blade life; The 2300 series parts are readily available, supporting the longevity and reliability of Carter band saw guides.

2400 Band Saw Guide Parts

Carter’s 2400 Band Saw Guide Parts represent a further refinement in component availability for their band saw guide systems. Similar to the 2300 series, these parts allow for targeted repairs and maintenance, extending the life of the guide assembly. This modular approach minimizes downtime and expense for woodworkers who rely on precise cutting performance.

The 2400 series parts often include upgraded bearing options and more robust mounting solutions, enhancing durability and reducing vibration. Sourcing genuine Carter replacement parts guarantees a precise fit and maintains the original engineering specifications. Consistent quality in replacement components is vital for preserving the accuracy and efficiency of the band saw. These parts ensure continued optimal performance.

Key Components of a Carter Band Saw Guide Kit

A typical Carter Band Saw Guide Kit comprehensively addresses the essential elements for improved cutting performance. Core components include both a lower and upper guide assembly, meticulously engineered to minimize blade drift and maximize stability. These guides feature precision bearings, crucial for smooth blade tracking and reduced friction.

Furthermore, each kit incorporates a new guard attachment, enhancing operator safety and containing sawdust effectively. A complete set of mounting screws is also provided, ensuring a secure and reliable installation. The quality of these individual parts, combined, delivers a substantial upgrade over standard band saw guide systems. This holistic approach ensures optimal functionality and longevity.

Compatibility: Jet and Delta Band Saws

Carter Band Saw Guides are specifically designed to fit popular band saw models from Jet and Delta, ensuring a straightforward upgrade path for many woodworkers. Recognizing the variations between manufacturers, Carter offers distinct kits tailored for each brand’s unique specifications.

Notably, the Model 39360 is explicitly engineered for Jet 14-inch band saws featuring round posts – a critical detail for proper fitment. It’s important to verify compatibility, as this model does not fit all Jet 14-inch saws. Delta band saw compatibility is also addressed with dedicated kits, guaranteeing optimal performance and ease of installation. Careful model matching is key to a successful upgrade.

Model 39360: Specific Fit for Jet 14 Band Saws

Carter’s Model 39360 guide kit is meticulously crafted for Jet 14-inch band saws that utilize round post designs. This kit provides a substantial improvement over stock guides, enhancing cutting precision and reducing blade drift. It’s a popular choice for woodworkers seeking to maximize the performance of their Jet saws.

However, a crucial caveat exists: Model 39360 is not compatible with Jet 14-inch band saws featuring square posts. Confirming your saw’s post type is essential before purchasing. The kit includes both upper and lower guides, alongside a new guard attachment and necessary mounting hardware, offering a complete upgrade solution for compatible Jet models.

Understanding Band Saw Guide Functionality

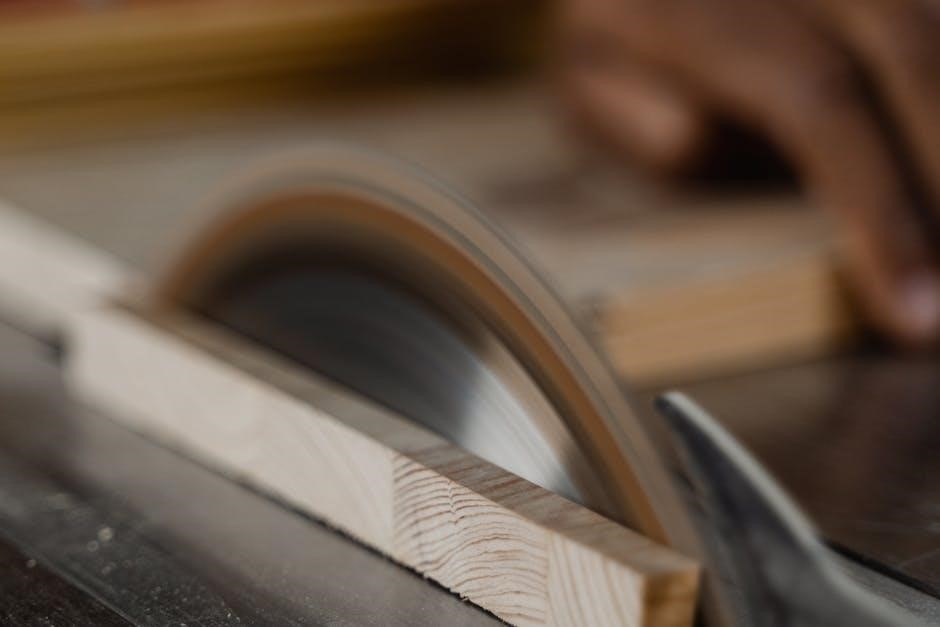

Band saw guides are critical components ensuring accurate and clean cuts. They control blade stability, preventing wandering and reducing the risk of blade breakage. The upper and lower guides work in tandem, supporting the blade throughout its cutting path. Proper adjustment is paramount; guides must be closely aligned with the blade without excessive pressure, which can generate heat and wear.

Effective guides minimize blade flex, particularly during resawing or cutting thicker materials. Upgrading to precision guides, like those from Carter, significantly improves cut quality and efficiency. They maintain consistent blade tracking, resulting in straighter cuts and a smoother finish, ultimately enhancing the overall woodworking experience.

Benefits of Upgrading Band Saw Guides

Upgrading band saw guides, particularly with a Carter kit, delivers substantial improvements in cutting performance. Users experience dramatically increased accuracy, reducing material waste and the need for extensive sanding. Blade life is extended due to reduced friction and stress, saving money on replacements. The enhanced stability minimizes blade drift, crucial for intricate cuts and resawing.

Furthermore, superior guides contribute to a safer working environment by preventing blade breakage and improving control. Carter guides offer precise adjustability, allowing for optimal setup for various materials and thicknesses. This translates to cleaner cuts, reduced vibration, and a more enjoyable and productive woodworking experience overall.

Riser Block Guard and Safety Features

Carter Band Saw Guides prioritize user safety with thoughtfully designed components, notably the riser block guard. This guard provides a crucial barrier, protecting operators from accidental contact with the blade, especially during resawing operations with a riser block installed. The design minimizes the risk of injury while maintaining visibility of the cutting process.

Beyond the guard, Carter kits include features that enhance overall band saw safety. Precise blade alignment and reduced blade flutter contribute to a more stable and predictable cutting experience. The robust construction of the guides themselves minimizes the chance of component failure. These features collectively create a safer and more controlled woodworking environment.

Materials Used in Carter Band Saw Guide Construction

Carter Band Saw Guides are renowned for their durability, stemming from the high-quality materials used in their construction. Primarily, these guides utilize precision-cast iron for the main body components, ensuring rigidity and vibration dampening during operation. This material choice minimizes flex and maximizes cutting accuracy.

Bearings are a critical element, and Carter employs sealed ball bearings known for their smooth operation and longevity. These bearings reduce friction, contributing to cleaner cuts and extended blade life. Additionally, hardened steel is used for key wear points, resisting deformation and maintaining precise alignment. The combination of these materials results in a robust and reliable guide system built to withstand demanding use.

Installation Process for Carter Band Saw Guides

Installing Carter Band Saw Guides is a straightforward process designed for DIY enthusiasts, typically requiring basic hand tools. The initial step involves removing the existing factory guides, carefully noting their placement for reference. Carter kits include both upper and lower guides, along with a new guard attachment.

Installation begins with mounting the lower guide, ensuring proper alignment with the blade. Next, the upper guide is installed, followed by the guard, secured with the provided screws. Precise adjustment is crucial; the guides should be positioned close to the blade without causing friction. Following the included instructions carefully guarantees optimal performance and a secure fit, enhancing your band saw’s capabilities.

Maintenance and Troubleshooting

Maintaining Carter Band Saw Guides ensures long-lasting performance and precision. Regularly inspect the guides for wear and tear, focusing on the bearing surfaces. Lubrication is key; apply a light oil to the bearings periodically to minimize friction and maintain smooth operation.

Common issues include blade drift, often caused by improper guide alignment. Adjust the guide posts to correct this. Excessive vibration can indicate worn bearings, requiring replacement. If the blade wanders, double-check the guide’s proximity to the blade – too tight causes friction, too loose causes drift. Consistent maintenance prevents problems and maximizes the value of your Carter guide investment.

Common Issues and Solutions

Blade drift is a frequent concern; ensure proper guide alignment by carefully adjusting the upper and lower guide posts. Excessive vibration often signals worn bearings – replacement is typically necessary for optimal performance. A wandering blade can result from guides positioned too close, creating friction, or too far, lacking sufficient support.

Difficulty with adjustments may stem from overtightened locking mechanisms; loosen slightly before making changes. Noise during operation could indicate insufficient lubrication; apply a light oil to the bearing surfaces. Regularly inspect all components for wear. Addressing these issues promptly maintains cutting accuracy and extends the lifespan of your Carter Band Saw Guides.

Purchasing Carter Band Saw Guides

Carter Band Saw Guides are readily available through various channels, including online retailers like Amazon and directly from the Carter Products website. Specialized woodworking supply stores, both physical and online, also stock these guides. When purchasing, verify compatibility with your specific band saw model – Jet and Delta saws have dedicated options (like model 39360 for Jet 14”).

Consider the specific series (Micro Precision, Guidall, 2000/2300/2400) based on your needs and budget. Comparing prices across different vendors is advisable. Ensure the kit includes all necessary components: upper and lower guides, and the guard attachment. Purchasing from authorized dealers guarantees genuine Carter products and potential warranty support.

Cost Considerations and Value

Carter Band Saw Guides represent a moderate investment, typically ranging from $150 to $400 depending on the series and specific components included. While seemingly higher than generic alternatives, the value proposition is substantial. The enhanced precision translates to reduced material waste, improved cut quality, and extended blade life, ultimately saving money.

Consider the long-term benefits: fewer blade replacements, less rework due to inaccurate cuts, and increased project satisfaction. The durability of Carter’s construction materials ensures longevity; Compared to the cost of a new band saw, upgrading the guides is a cost-effective solution for significantly improving performance.

Alternatives to Carter Band Saw Guides

While Carter Band Saw Guides are highly regarded, several alternatives exist. Kreg offers band saw guides, often positioned as a more budget-friendly option, though potentially sacrificing some precision. Highland Woodworking provides guide systems, focusing on robust construction and adjustability. Some woodworkers opt for fabricating custom guides, requiring significant skill and time investment.

Generic aftermarket guides are available at lower price points, but frequently lack the quality materials and precise engineering found in Carter products. Evaluating specific needs – budget, desired accuracy, and DIY capabilities – is crucial. Ultimately, the best alternative depends on individual priorities and the intended use of the band saw.

Customer Reviews and Feedback

Customer feedback on Carter Band Saw Guides is overwhelmingly positive, consistently highlighting improved cut accuracy and reduced blade drift. Many users report a noticeable difference in finish quality, particularly when resawing. Installation is generally described as straightforward, even for those with limited mechanical experience.

Common praise centers on the guides’ durability and the quality of materials used. Some users mention the initial cost as a consideration, but quickly justify it with the long-term benefits of increased precision and reduced blade replacement. A few reviews note that proper adjustment is key to maximizing performance, emphasizing the importance of following the included instructions carefully.

Where to Find More Information

For detailed information regarding Carter Band Saw Guides, the official Carter Products website (carterproducts.com) is the primary resource. It features comprehensive product specifications, detailed installation guides, and frequently asked questions. Numerous online woodworking forums, such as WoodworkingTalk and Sawmill Creek, host dedicated threads discussing user experiences and troubleshooting tips.

YouTube channels specializing in woodworking, like The Wood Whisperer and Stumpy Nubs, often feature reviews and demonstrations of Carter guides. Retailers like Amazon and Rockler also provide product information and customer reviews. Checking these sources will provide a well-rounded understanding of the guides’ capabilities and suitability for specific band saw models;

The Legacy of Jimmy Carter and the Brand

The Carter name isn’t simply branding; it reflects the integrity and work ethic of Jimmy Carter himself, a former peanut farmer, Navy officer, and 39th President of the United States. While his presidency focused on human rights and peace, the Carter brand, established before his political career, embodies a commitment to practical, high-quality tools.

Carter Products began with a focus on woodworking solutions, and the band saw guide line exemplifies this dedication. The brand’s longevity – surviving decades and a changing market – speaks to its consistent quality and innovation. It’s a testament to Carter’s values of hard work and providing reliable products for craftsmen.

Future Trends in Band Saw Guide Technology

Looking ahead, band saw guide technology, including that of Carter Products, is poised for further refinement. Expect increased integration of advanced materials – potentially lighter, stronger polymers or alloys – to reduce friction and improve stability during cuts. Digital adjustments and micro-precision settings, controlled via smartphone apps, could become commonplace, offering unparalleled accuracy.

Furthermore, modular designs allowing for greater customization based on blade width and material type are likely to emerge. Self-lubricating guide systems minimizing maintenance and enhanced dust collection features are also probable developments. Carter’s established reputation positions them well to lead these innovations, continuing their legacy of quality and precision.

In summary, Carter Band Saw Guides represent a substantial investment for any serious woodworker seeking enhanced precision, control, and longevity from their band saw. Rooted in a history connected to Jimmy Carter’s commitment to quality and innovation, these guides consistently deliver superior performance across various models, notably Jet and Delta.

From the Micro Precision Series to the robust 2000 and 2300/2400 parts, Carter offers solutions for diverse needs and budgets. Upgrading to Carter guides isn’t merely about replacing parts; it’s about elevating the entire sawing experience, improving cut quality, and extending blade life. They remain a benchmark in the industry, embodying a blend of tradition and technological advancement.